LVT stands for Luxury Vinyl Tile. It was designed to replicate natural hard flooring, like wood and stone, whilst being more affordable, durable and easier to maintain. The product was developed in the 1930s and became extremely popular after the war in residential, commercial and institutional environments. However, it has moved on a great deal from being the thin sheets in the 1960s and 1970s, to a product which is technically advance, high quality and convincing. It is being constantly developed for use in a wide range of applications.

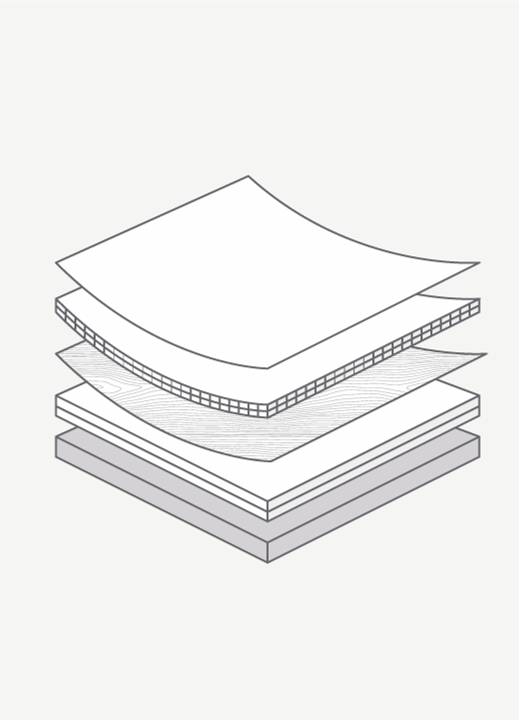

The Construction

All LVT products are made up of some variation of the following layers: wear layer, photographic layer, core layer and backing layer. Depending on its function, the product will have this composition, but may vary in thickness, with some added layers to give additional properties.

The wear layer is the top surface of the tile and comes in thicknesses between 0.3mm and 1mm. This layer is hardwearing and embossed to replicate the texture of the natural material. The thicker the wear layer, the more durable the tile will be against traffic, scuffs and cleaning. In a workplace, it is recommended to specify a wear layer of between 0.5mm and 0.7mm depending on the amount of footfall the space is likely to receive.

The photographic layer is a high-definition printed film which visually imitates the natural product.

The core layer is a high-performance, non-rigid layer which provides extra stability and durability. It makes up the majority of the tile.

Finally, the backing layer is at the base and is what gets adhered to the subfloor or raised access floor. This high vinyl content backing provides a robust foundation and impact resistance. Depending on the type of tile, it will have a high surface area which creates a natural grip to the under-floor.

Loose-lay

The term ‘loose-lay’ refers to the type of vinyl tile which can be installed directly onto the subfloor with minimal or no adhesive. This product tends to be between 4mm and 5mm in thickness and generally has a wear layer of above 0.5mm. These tiles are the thickest, which give them a higher acoustic performance than any other vinyl tile. Although the cost of the product itself tends to be higher, there is a saving in labour costs. This product can hide imperfections of a subfloor with a tolerance of 5mm, meaning that there is little or no preparation needed (e.g. plywood or latex) so installation is much easier and quicker. The lack of adhesive means that if it is laid over a raised access floor, a tile can easily be lifted to access the pans and services without causing damage. The thickness of the product also means that it can be laid directly next to carpet tiles (typically being same thickness) without any preparation. The disadvantage of these products is that there a limited number of finish options in the ranges and the overall look and feel is less realistic to the natural material.

Adhesives

It is important to note that adhesives contaminate the product, meaning that at the end of its use, it cannot be recycled. It is always worth questioning whether adhesive or tackifier is absolutely necessary when laying a loose-lay product.

Glue Down

Glue down products are typically more design-led than loose-lay products. The thickness of the tiles vary between 2mm to 3mm with wear layers of up to 0.7mm. The wear layer makes the product extremely durable, but also gives a more realistic finish. The tiles are usually heavily embossed and bevelled, giving a higher quality feeling. Most manufacturers offer a huge range of finish options, and tiles can be supplied in a wide range of shapes and sizes. This means that there are an almost infinite number of laying patterns and combinations. A glue down product is a great way to get creative and achieve a high-end finish which looks great and stands the test of time. Although the product tends to be cheaper to buy, it is often more expensive to install. Due to the tile’s relatively thin profile, it cannot hide imperfections in the underfloor and latex or plywood is often required to level the underfloor prior to laying. The product also requires adhesive to hold the tiles in place and because of the many different laying pattern options, the process of laying the tiles themselves can take longer.

Conclusion

Loose-lay is a good solution when prioritising practicality and when saving time and money is important. If sustainability is top on the priority list, a loose-lay product might be more effective if you can confirm that no adhesives will be used. The product will give a durable and long-lasting effect, but might fall down when compared to glue down products in terms of look and feel if the quality of the design is important. A glue down product will probably be the right way to go if the mood of the space is important and durability is a key factor.

Vinyl flooring has been around for decades and when it comes to commercial spaces, it can feel overwhelming when you start to explore the different product options. When it comes to making a decision on which type of vinyl tile is required for your space, an important place to start is to think about the function of the space and what it is you are aiming to achieve. From there, you should be able to narrow down the options and choose a product which will inevitably be good quality, hard wearing and appropriate for the space.