Building Information Modelling (BIM) has been used in construction for around 20 years, and the UK government mandated its use in public sector building projects in 2016.

BIM enables a virtual 3D information model to be shared amongst the design team, the main contractor, subcontractors, and the owner/operator. So how does BIM aid facilities managers? There are many advantages of using BIM over traditional 2D technical drawings. Because all stakeholders work together to produce a single model, it encourages collaboration and reduces uncertainty in the design process. This leads to improved efficiency, less risk and significant cost savings.

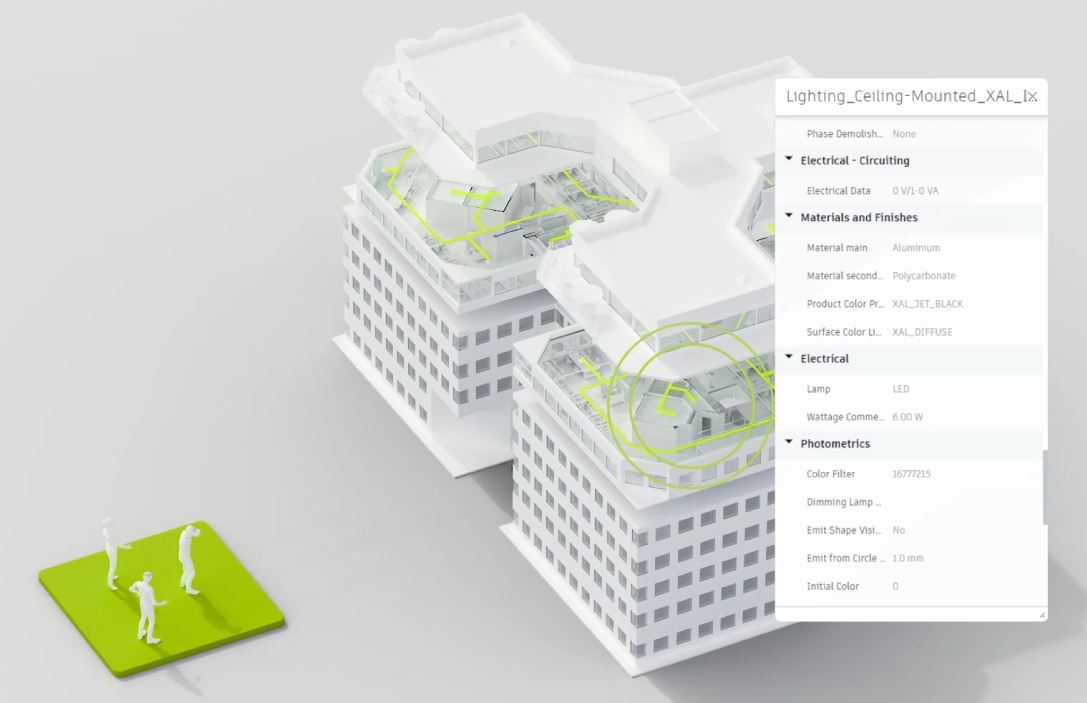

Example of a BIM model, created by Mobius At Work

Facilities Managers involved in the BIM construction process will be part of the team. They oversee the implementation of systems and protocols for building handover on completion. They will benefit from a smooth transition of information. The hosted data-rich 3D model can replace the traditional Operation and Maintenance Manual. Assets can be tagged and incorporated within BIM software to support analysis. This can include dynamic information about the building, such as sensor measurements and control signals from the building systems. In the post-Covid era, when so many companies are embracing a hybrid working model, occupancy sensors and booking systems can also be added.

For buildings that have already been constructed, it is still possible to bring all the benefits of BIM by working in partnership with a company skilled in the process. This company will conduct a laser point cloud survey, scanning the building to capture the architectural geometry and create a highly accurate 3D model. Once the architectural model is created, adding mechanical, electrical and plumbing services as-built in the physical building is possible. Along with the previously mentioned sensors, these models are now referred to as ‘Digital Twins’.

Example of a ‘digital twin’ by Mobius At Work

Costs are associated if a retrospective Digital Twin is created as a stand-alone asset. However, if fit-out works are required in the building, a fit-out company working in BIM as a standard workflow will often offset those costs against project works. There are considerable advantages to using the BIM workflow for a fit-out. These companies use BIM to facilitate collaboration between the client, the design team and the contractors. Creating a fully textured twin of the project space to engender cooperation, reduce risk and produce time and cost savings compared with the traditional RIBA design and build process.

Example of an office digital twin by Mobius At Work

Once the fit-out is complete, the Facilities Manager should be able to maintain and operate the building using the Digital Twin. Since every fixture and fitting in the model should be tagged with data, replacing the carpet or ordering another chair will be quick and easy. Suppose there is a leak above the ceiling. In that case, the Facilities Manager should quickly ascertain from the 3D model what mechanical or plumbing item above the ceiling may be the cause.

Once the Digital Twin has been produced, it can be referred to and utilised for additional works as and when required. It enables teams to share information and create accurate programmes and budgets.

Interested in BIM? See how it can aid a more sustainable fit out by reading our next blog.